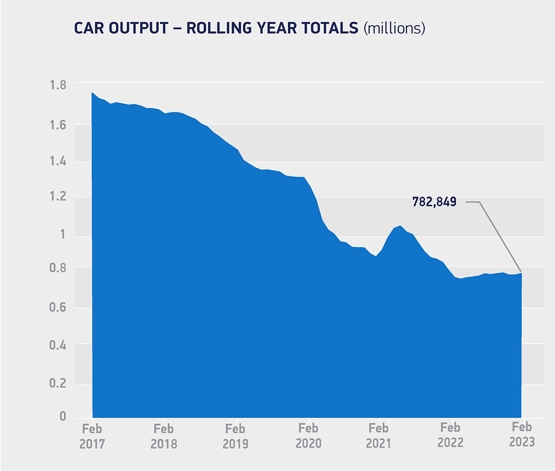

Society of Motor Manufacturers and Traders (SMMT) chief executive Mike Hawes has said the UK’s car manufacturing sector is “on the road to recovery” following a 13.1% growth in production volumes in February.

His comments come just a month after a 0.3% decline prompted the automotive manufacturing sector chief to suggest that economic conditions in the UK had made it an “unattractive” proposition for manufacturers.

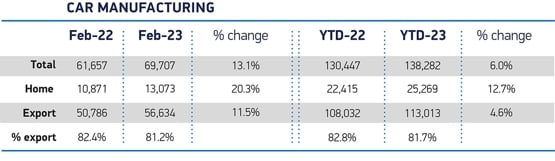

After today’s (March 20) news that February production had delivered double-digit volume growth – with 69,707 units leaving factories – Hawes said: “February’s growth in UK car production signposts an industry on the road to recovery.

“The fundamentals of the sector are strong; a highly skilled workforce, engineering excellence, a sector that is embracing new electrified vehicle manufacturing and wide-ranging capabilities in the EV supply chain.

“The fundamentals of the sector are strong; a highly skilled workforce, engineering excellence, a sector that is embracing new electrified vehicle manufacturing and wide-ranging capabilities in the EV supply chain.

“To take advantage of global opportunities, however, we must scale up at pace and make the UK the most attractive destination for automotive investment by addressing trading and fiscal costs and delivering low carbon, affordable energy.”

The SMMT said that carmakers had been buoyed by an easing of supply chain shortages – notably of semiconductors – which have “bedevilled the global industry” since the early months of 2021.

Its data showed that hybrid, plug-in hybrid (PHEV) and electric vehicle (EV) output surged by 72.2% last month, accounting for two-in-five cars produced.

Production for the UK’s home market rose 20.3%, with 11.5% growth in units destined for export.

Production for the UK’s home market rose 20.3%, with 11.5% growth in units destined for export.

The EU accounted for 59.6% of the 56,634 cars destined for overseas markets.

Shipments to the EU rose 6.5%, as exports to Turkey, Japan, Australia and South Korea collectively rose by 85%.

This helped to offset a decline in exports to the US (down 19.9%) and China (down 21.6%)

News of growth in the UK’s car manufacturing output during February followed the SMMT’s March publication of Race to Zero: Powering Up Britain’s EV Supply Chain report.

The blueprint for how the UK can boost its electric vehicle manufacturing in the face of fierce global competition included a new UK EV Supply Chain Directory, which illustrates how, from batteries, powertrains, fuel cells and power electronics to anodes, rare earth magnets, graphene and silicon carbide wafers, the UK already produces almost every component needed to make electric vehicles.

“The challenge now is to scale up this capability, harness the UK’s strengths in advanced automotive manufacturing, low carbon energy and R&D and deliver growth for the sector”, the SMMT said.

While the SMMT reported that automotive businesses are broadly optimistic about the next 12 months, “cripplingly high and uncompetitive energy costs” ranked as their number one concern.

Support on business rates, easing supply shortages and access to trade are also all viewed as beneficial for growth.

Commenting on today's production figures, carwow consumer editor Hugo Griffiths said: “We may, whisper it, be seeing significant improvements in almost every sector of the UK car industry. Production in February being up by 13.1% is the latest positive measurement, and it follows hot on the heels of last month’s new-car registrations, which were up by more than a quarter.

“carwow’s trading conditions echo these trends: the firm is enjoying one of its most successful quarters ever with record numbers of enquiries, configurations and sales across new and used markets, and the firm’s partner dealers reporting both strong interest, and improving levels of stock supply.”

Login to comment

Comments

No comments have been made yet.