Two decades of using the world wide web have seemingly left many consumers intent on instant gratification. However, the UK’s motor retail industry still makes many customers wait before they can drive away in their new car.

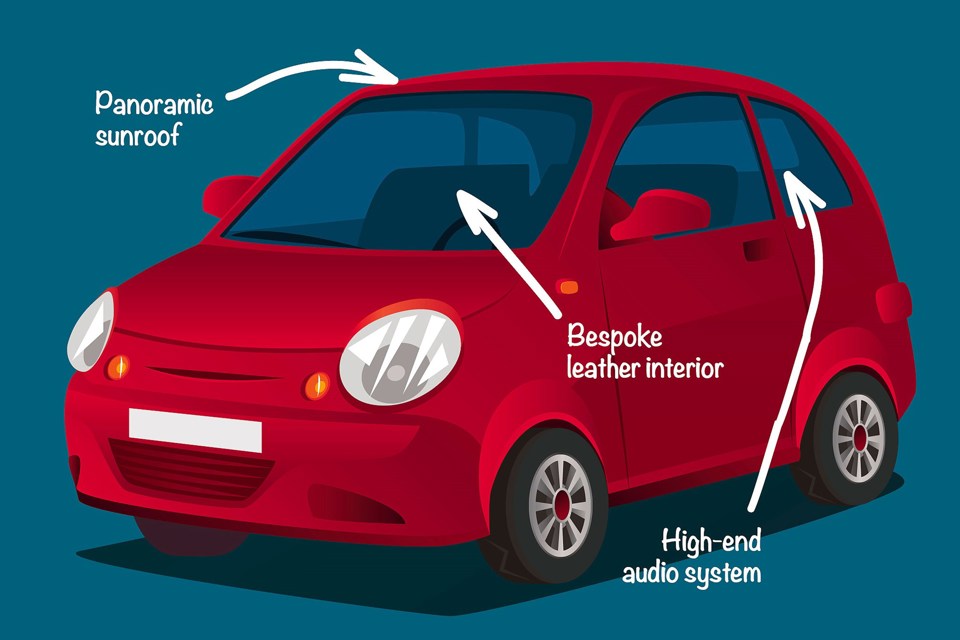

The options on many new car configurators enable customers to tailor their chosen vehicle to their needs. Because it increases the invoice value, the dealer’s profitability will benefit. But is providing choice to the consumer about to become a burden for the industry?

Personalisation is a good thing as long as the gap between order and delivery doesn’t become too long and lead to frustration and dissatisfaction, according to Keith Janes, Ford brand manager at Essex Auto Group. He said the introduction of a large interactive ‘power wall’ in FordStores has helped dealers show how additional features could enhance a vehicle.

“Customers want choice and a degree of personalisation when purchasing their next vehicle, and the higher the selling price the more prevalent this becomes – we’ve seen this with the new Mustang,” he said.

Janes added that personalisation allows dealers to use marketing driven by lifestyle rather than purely price or payment, particularly across web and social channels.

However, he believes the industry needs more robust systems to accurately monitor a vehicle’s movement through the build and delivery cycle.

Ben Waller, associate director at the ICDP, agrees. In a 2014 ICDP study, one in four buyers reported that the estimated delivery date given by their dealer had changed.

ICDP research from 2012 found 35% of volume brand customers were prepared to wait more than 30 days from order to delivery. This rose to 57% of customers at premium brands.

Waller told AM the customer needs more transparency on the pros and cons of buying from stock versus factory order, and manufacturers’ customer-facing platforms should allow the prospective buyer to understand the lead time implications based on availability and configuration. The buyer could then balance their need for the car against their desire for particular features.

“Product variety has exploded in Europe over the last 20 years,” he said. “Some volume cars already come in a bewildering array of combinations that many salespeople struggle to understand, let alone customers.”

Compared with Europe, ICDP data shows that US dealers offer about half the possible engine-body-paint-trim combinations for Asian and volume brands, and a third of the premium brand combinations. As a result, they typically hold vast new car inventories and buyers may drive away on the day of purchase.

However, Janes doesn’t believe larger stock holdings are the answer. More important, he said, is “central fluidity” within the total manufacturer and dealer inventory, with vehicles always available wherever the demand occurs.

Professor Jim Saker, director of the Centre for Automotive Management at Loughborough University, finds it interesting that products heavily focused on younger buyers, such as Mini, Vauxhall Adam and Fiat 500, have extensive personalisation options, but this has not held back their sales. This is despite the argument that younger consumers are looking for instant gratification and access rather than ownership.

Brand perception and expectation – whether a car is positioned as made to measure or off the shelf – are critical. One issue for the industry is the lack of research into how a customer actually goes about configuring a car online. Saker said evidence from other sectors suggests that if the process is too complicated, the customer will simply opt out. This could work in the dealer’s favour, if they seek advice.

“An in-dealership configuration service has the potential to generate footfall, especially if any work done by the customer at home can be transferred so they don’t have to start again,” he added.

Waller believes there is less conflict between personalisation and instant gratification now than there was 25 years ago. Vehicle supply chains have become more flexible – although he said there is scope for improvement – and some brands support late customisation at their UK central processing/storage facilities or by the dealer, such as trim parts changes or decals, to allow more personalisation immediately prior to delivery.

He also suggested that the pushing of new car supply into the UK has narrowed the focus of manufacturers and dealers, so they are actually not selling their full product variety because of high stocks. For premium brand dealers, this can harm profitability if they are not selling more build-to-order cars.

Rupert Pontin, director of valuations at Glass’s, said it is generally accepted within the trade that the current level of choice can help to sell new cars, but it does risk creating increased complexity and confusion in ordering for both manufacturers and consumers. He warned that complex vehicle requests could be misread, leading to mis-builds becoming more commonplace, and creating unique stock that may be harder to place with another customer.

Marc Palmer, manufacturer brand director at Auto Trader, believes that because of production lead times, dealers will always avoid marketing ‘too much’ personalisation simply because there is too much of a risk a customer will change their mind, leaving the dealer landed with a car they cannot sell.

Where the customer does desire personalisation, but there are lengthy lead times, the buyer and the dealer will resolve this together, said Palmer.

“Often the buyer will have a specific vehicle configuration in mind, but will be unaware that lead times may be long. If there’s time pressure they have always found a compromise with the dealer, such as taking a slightly different colour or interior, and this won’t change,” he added.

Neil Hunt - 10/04/2017 13:30

The key to successful personalisation is ensuring the process behind it does not harm the sales process, as many of the industry experts have mentioned. I worked as part of a team at Toyota that transformed their sales - by making it easier for the Sales team to order accessories, and giving them clarity on any increase to the lead time. These options were fitted at Port of Entry, rather than 'Build to Order' factory options. Adding customisation once the vehicles are in the country not only gives greater control over lead-times, it also saves the OEM with any stock issues. As the standard models are held in stock, and the options are fitted on demand. Of course, Toyota had a very strong process-orientated 'Port of Entry' operation, which helped make this such as a success. But I am surprised more people have not grasped this opportunity, as there are literally millions of pounds of untapped sales opportunities being missed.